Industrial Torque Converters

Industrial Hydraulic Torque Converters

Herman Fottinger, a German engineer, patented the first torque converter and fluid drive in 1905, which began the technological movement toward automatic transmission. His invention was licensed to several engine manufacturers in the 1930s.

The majority of engines back then had a manual transmission. The engine was directly connected to the driveline and gearbox in early designs. As a result, the engine would stall every time the machine came to a complete stop. So manufacturers added a clutch to keep the engine running after the driver hits the brakes, which separates the gearbox from the engine.

Torque converters replace the clutch system and use fluid coupling. Unlike manual transmission, it uses fluid to deliver the power from the transmission and prevents engines from stalling. It has the following components:

- Pump: The centrifugal pump is designed to rotate the fluid inside the converter using a vacuum, moving the fluid toward the outer sections of the system.

- Impeller or Turbine: The expelled fluid enters the impellers or turbines connected to the vehicle’s transmission. As the turbines rotate, the transmission spins, making the vehicle move.

- Stator: The fluid from the impeller is then redirected back to the turbines by the stator. This component completes the fluid cycle, drastically improving the engine’s overall efficiency compared to manual transmissions.

- Transmission Fluid: The transmission fluid flows through all system components. As this fluid flows from the pump to the stator, it lubricates all parts, ensuring optimal performance.

Transmission fluid tends to flow faster as the engine’s crankshaft rotates faster. As a result, more torque is produced as the turbines spin more quickly. However, when the engine idles, the flow of the transmission fluid slows down, producing less torque.

A torque converter maintains the same gear ratio at all times. In contrast, torque converters are better if you want low-end torque. They also have a better ability to adjust the gear ratio according to the RPM of an engine. Because of this, torque converters are better for off-road vehicles and heavy equipment.

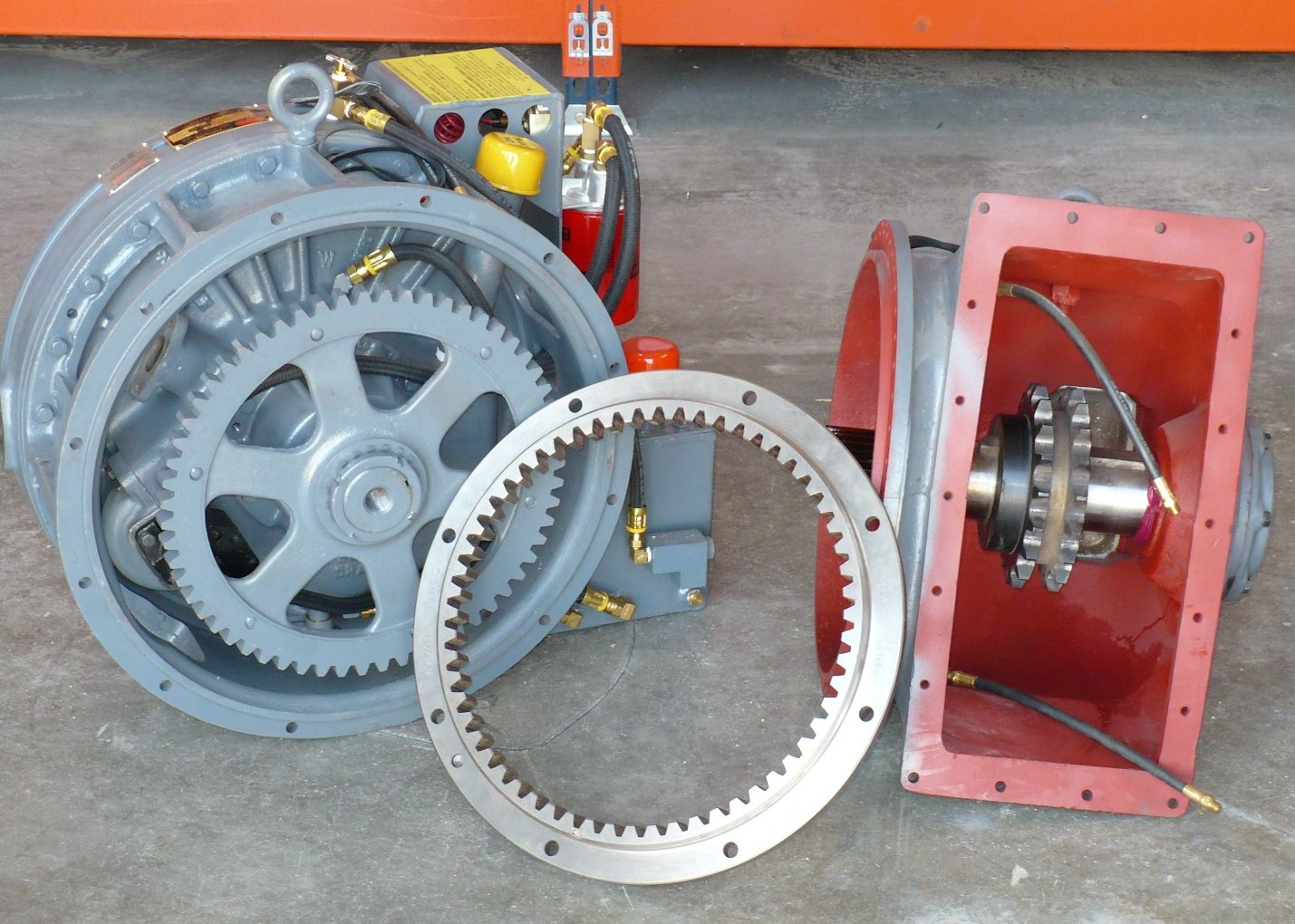

Extensive Torque Converter and Component Parts Inventory

Fitz Torque Converters has a large inventory of torque converter parts for FIP, National, Twin Disc, and Allison hydraulic torque converters. With an extensive inventory of torque converters and torque converter parts, we have the ability to ship the same or the next day to minimize your downtime. Fitz can provide both exchange units and outright purchases on all models. Fitz does not limit the sale of torque converters to just the continental United States but offers products worldwide.

FIP Torque Converter

Fitz went into the manufacturing business of torque converters in 2012 with our first line of torque converters, the C195 model. Later adding the C300 to the FIP Torque Converter line, these units are available for horsepower in the ranges of 350-1300hp. Our units are currently running worldwide.

FIP C195 Torque Converter

The FIP C95 torque Converter comes in both the Type “F” or Basic Converter and the Type “FH”. Please click here for more details on this model converter.

FIP C300 Torque Converter

The FIP C300 Torque Converter comes in both the Type “F” or Basic Converter and the Type “FH”. Please click here for more details on this model converter.

National Torque Converter

The national torque converter is a single-stage torque converter designed for higher peak efficiency with minimal moving parts. Fitz specializes in National torque converters of all models, C195, C245, and C300. Fitz maintains an extensive inventory of complete units and replacement parts which allows for quick delivery and turnaround. Complete units and parts are normally in stock and ready for same-day shipping.

Operational Features

Maximum torque available during peak power requirements

Reduced engine maintenance and overhaul costs

Fewer liner sizes required when pumps are driven by torque converters

Maximum flexibility and complete control through the entire load range

Reduces or eliminates shock to equipment

Does not overheat while operating at light loads

Design Features

One pump performs both functions

Chain driven; easily adjustable

Removable as a unit

High-capacity flow rate permits more efficient oil cooling

Accessible from outside of sump

Oil filters externally mounted and easily removed

Pressure and temperature gauges are shock-protected and easily replaced

Converter Sizes

- 195VIEW SPECS

- 245VIEW SPECS

- 300VIEW SPECS

Twin Disc Torque Converter

Twin Disc offers single-stage hydraulic torque converters of both stationary and rotating housing types and a three-stage hydraulic torque converter. The Twin Disc Three-Stage torque converter design, incorporating three rings of turbine blades and two sets of reactor or stator blades, develops a very high torque factor-up to five times engine output torque when at stall. The 10,000 series is rated for applications up to 335 hp at 2400 rpm; the standards-duty 11,500 series to 420 hp at 2200 rpm; the heavy-duty 11,500 series to 800 hp at 2200 rpm.

Model F Units

Bolts directly to the engine flywheel housing. A positive gear-tooth drive transmits power from fly-wheel with no clutch. Model F input drive is available on all sizes.

Model FO Units

Model FO units are open-end, flywheel-mounted torque converters with overspeed or boom-lowering freewheel. Units are available in the 10,000 series.

Input & Output Combinations

A variety of output combinations is available with various three-stage converters. Type B is a chain housing. This is available with the 10,000 and the standard-duty 11,500 series. Type C-1 output is a straight shaft for direct connection to the driven load; the Type C-2 is a flanged shaft for universal joint connection; Type C-3 is similar to the Type. The heavy-duty 11,500 series converter is offered with a heavy-duty type C-3 output. This series is adaptable to all applications required to withstand heavy side-pull loads.

Twin Disc Fluid Couplings: 27” HUD-00

Performance to 1500 hp @ 1500 rpm

The Model 27-inch HUD is a disconnect-type fluid coupling P.T.O which when used in a drive train eliminates the need for a disconnect clutch. The disconnect feature can be rapid or normal. Normal disconnect is provided by bleeding the coupling oil through orifices located at the periphery of the coupling. If quick disconnect is required, an optional set of four dump valves can be ordered. The dump valves, using no sliding parts or rubber connections, open large ports to rapidly exhaust the coupling oil. Dump valves can be installed in the field if not ordered originally, but desired.

National Torque Converter

The national torque converter is a single-stage torque converter designed for higher peak efficiency with minimal moving parts. Fitz specializes in National torque converters of all models, C195, C245, and C300. Fitz maintains an extensive inventory of complete units and replacement parts which allows for quick delivery and turnaround. Complete units and parts are normally in stock and ready for same-day shipping.

Operational Features

Maximum torque available during peak power requirements

Reduced engine maintenance and overhaul costs

Fewer liner sizes required when pumps are driven by torque converters

Maximum flexibility and complete control through the entire load range

Reduces or eliminates shock to equipment

Does not overheat while operating at light loads