Industrial Air Compressors

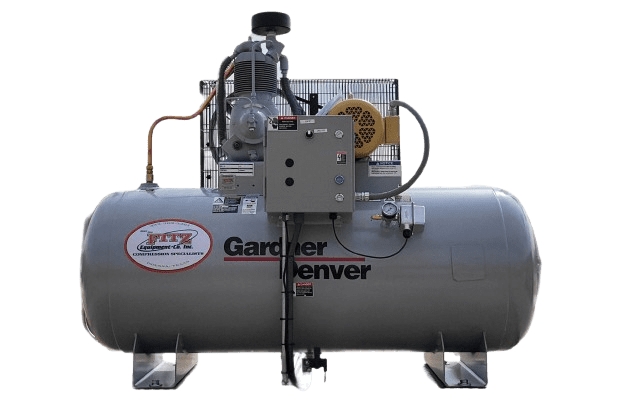

Industrial Air Compressors for Sale from Fitz Equipment

Fitz Equipment Company can handle all your industrial air compressor needs. We have new and rebuilt industrial air compressors for sale, units are available for Gardner Denver, Joy, FS Curtis and Champion air compressors, Bauer low volume high-pressure air and breathing air compressors, and Kaeser engine driven portable compressors.

Remanufactured & Rebuilt Industrial Air Compressors for Sale

Fitz Equipment has the best Gardner Denver industrial air compressor remanufacturing facility in Texas and the surrounding states. Every remanufactured air compressor unit is completely torn down, vatted, and sandblasted. Crank shafts are magnaflexed and connecting rods are run through the machine shop to check for correct OEM tolerances. Everything is completed according to Gardner Denver specifications and only factory parts are used. Remanufactured air compressor units come with a six-month warranty.

Industrial Air Compressor Parts for Sale

We also have a variety of older industrial air compressor units for sale and replacement parts as well as customized units. Fitz Equipment also sells and services air hoists, including Ingersoll Rand remanufactured units.

Gardner Denver Industrial Air Compressors

Lubricated Rotary Vane Vacuum Series:

The Gardner Denver rotary vane vacuum pump line provides more capacity with lower installed power than other oil-lubricated pumps. With 17 sizes from 2 to 918 CDF, the Gardner Denver rotary vane line represents the largest selection of rotary vane pumps for your application.

Multi-Claw Vacuum Air Compressor:

The Gardner Denver Claw Series vacuum pumps and compressors utilize a highly evolved claw design for dry, frictionless compression- efficiently and economically.

Wittig RFL:

Due to their advanced design and precision of construction, these machines make very economic use of the oil injected in the compression chamber for lubrication and sealing. They are fitted with an automatic lubrication system, which supplies oil to all contacting parts of the machine. The oil pump is mounted within the oil tank and is driven directly by the rotor shaft. The compressor/vacuum pumps are often installed on vacuum tankers carrying contaminated sludge. They are extremely robust, require very little maintenance, and are simple to operate.

An ideal air cooling system powered by two fans, ensures the best cooling effect, even on extended runs

A generously proportioned oil tank allows extended run periods

Integrated oil pump for continuous and reliable oil supply

Sight glasses on both sides of the machine for ease of oil level checks

Central mounting point for the easy fitting of a hydraulic drive motor if required

Dimensions at shaft ends suitable for alternative V-belt drive

Mounting feet attached to top or underneath of the machine allows a standing or suspended installation

Portable Air Inc. Portable Industrial Air Compressors

Portable Air Inc. was established in 2010 to better serve our oilfield operations. With both rental and sales of portable diesel-powered rotary screw air compressors. This branch was added to eliminate costly downtime at drilling or plant locations. Portable units are available 24/7 for both pickup and delivery to your site. Units are available for daily, weekly, and monthly rentals, and new units are available for purchase at a competitive price.

Kaeser Engine Driven Portable Compressors

Kaeser portable compressors are built for rugged use and dependability. They provide a reliable source of compressed air for many industry applications. The large fuel tank provides over 10 hours of run time and has a large filler neck with overflow protection for easy and safe filling. The unit is built from industrial-grade materials that resist rust and corrosion. The Sigma Profile airend provides more air with less fuel consumption. Unit includes a high-capacity, cold-start battery, and the heavy-duty diesel engines comply with EPA emissions standards.

Specifications:

Capacities: 50 to 950 cfm

Standard Pressures: 100 to 145 psig